A silkworm develops from the egg of a delicate butterfly, known as a silkworm. From the very beginning, the little silkworms feed on tender mulberry leaves. During their development, they go through four moulting stages, during which they are tired and weakened and do not feed. After each stage, the grower cleans and changes the leaf bed and provides enough space for each silkworm.

The silkworm eats exclusively mulberry leaves, and during its 30-day life it eats about 1,000 kg of leaves, which it shreds into thin strips before swallowing. After a period of intensive feeding, the silkworm stops eating. The growers then place small twigs of heather or broom on the leaf bed. The silkworm climbs up these and begins to produce a fiber that hardens in contact with the air, creating a silk thread. This thread is used to build a mesh hammock where a cocoon is formed.

The cocoon is a figure-8-shaped chamber, 4-5 cm in size, that the silkworm builds by winding threads from the outside inward until it becomes trapped. The butterfly uses a special secretion to open the end of the cocoon and emerge. Once outside, the butterfly lays eggs (from 300 to 700) and after completing its reproductive function, the butterfly dies, completing the life cycle of the silkworm. Only 60 days pass from life to death.

To prevent the pupa from becoming a butterfly and breaking through the cocoon, the cocoons are boiled at 80°C for an hour, which causes the pupa to die. The dry cocoons are ready for the silk thread to be drawn out, which is called winding. The dry cocoons are placed in hot water to partially dissolve the sticky substance around the thread, called sericin, which can then be unwound. The silk obtained from this operation is called wound silk or raw silk.

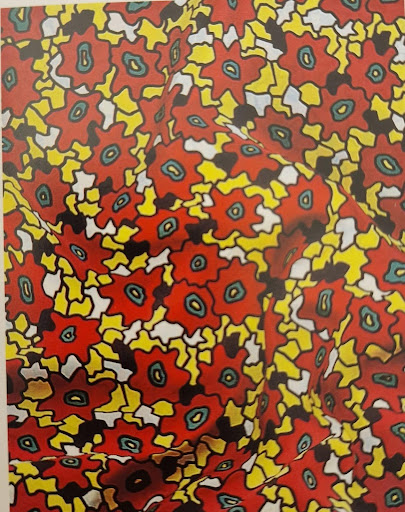

Raw silk contains almost all of the original glue, making it coarse and opaque and not easily dyed or bleached. Unboiled silk is raw silk that has undergone a light wash, while in semi-boiled silk the wash is heavier and a greater sheen can be observed. In boiled silk, the glue is completely removed, revealing a shiny silk.

The raw threads obtained by winding are subsequently subjected to twisting and retwisting by joining two or more layers, which is called throwing. Winding and twisting produce two types of yarn: organza, made from the best quality raw silk, and tram, made from lower quality silk. To add weight to the silk, it is immersed in a bath of mineral salts, which is called silk weighting. After a long process, we obtain silk yarns ready for weaving.

References: Nodus no. 3